- Home

- Services

- Hi-Line Engineering

- About

- Careers

- Contact

- Requests For Proposals

ERCOT Artic Blast - The Real Failure

by GDS Associates, Inc | March 31, 2021 | News

Much has been written about the February events that led to extensive failures of the equipment and facilities of the ERCOT power grid. The tragic loss of life and significant financial pain have grabbed headlines and precipitated weeks of hearings and meetings among Texas policymakers and industry.

Clearly there were failures up and down the whole supply chain, with the biggest failure, in my opinion, being a breakdown of communication. In fact, I believe much of this catastrophic failure could have been avoided if we had better communication among all the entities.

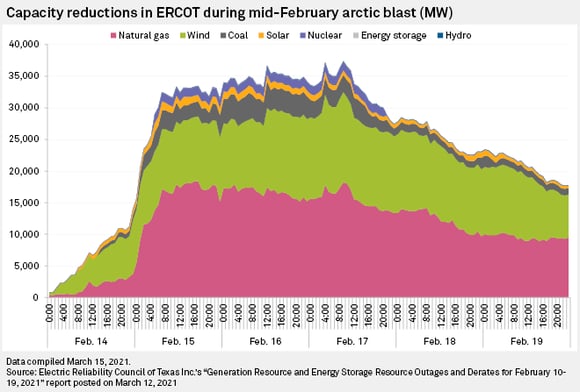

There has been a lot of discussion on mandating winterization of electric facilities, but without meaningful improvements to the gas infrastructure, electrical weatherization will not bring much benefit as approximately half of the generation lost was gas fired (see graph below), of which most of that was due to a loss of fuel supply. The gas industry points back to the electric industry as the cause of its supply woes.

While there is some need for winterization, some very simple and cost-effective solutions can be implemented, that can make a real difference here and in the near term. These solutions do not require significant capital, drastic market structure changes or years to implement. While these probably wouldn’t have eliminated the need to cut load entirely, they could have significantly reduced the amount and perhaps duration so that these outages could have been truly rotated.

So, the question is the following: If all the gas facilities from wellheads to processing plants to pipeline compressor stations had been properly identified on the Critical Infrastructure list and not been curtailed, how much more gas would have been available? This would mean more generators would have stayed online and, therefore, less load would have been cut. Some work is needed on the Transmission Distribution Service Provider (TDSP) side as well. As more critical infrastructure is identified and as seen with this event, taking outages by open circuits doesn’t work. Distribution-level outages need to be executed at a more granular level.

An obvious example was in downtown Austin. There were pictures all over social media of downtown Austin lit up like a Christmas tree during the winter storm. Empty parking garages were fully lit. Why did this happen? Well, if you open the circuit that feeds a major section of downtown Austin you are taking out empty office buildings, but you are also taking out a hospital, condos, apartments, police stations, etc. Opening a circuit does not allow outages to distinguish between critical facilities, like a hospital, from non-essential loads, like parking garages. But there is a superior option, we have been paying for Automatic Meter Reading (AMR) for years. This gives the utility the ability to remotely read and control each individual meter. We need to put this technology to work to help if or when we need to implement load reduction.

On the ERCOT side of things, it would help if they would change the way they deploy intermittent gas generation in the days ahead of a forecast of drastic cold conditions.

Finally, there was confusion on the prioritization of gas supply. Peaker units cannot normally justify the cost of purchasing both firm gas supply and firm transport as they run so few hours across the year. This resulted in many of these units not being online in peak hours, magnifying the crisis. Normally, electric peaks occur in the summer, not at the same time as heating peak; so, the gas supply plan for peakers do not normally expect an event like the winter storm. This issue can be easily fixed as well.

The following are recommended changes to improve the resiliency of our power grid:

- The Texas Railroad Commission (TRRC) needs to have the authority to ensure that all of the players in the gas industry have identified ALL facilities associated with the gas supply and transportation network to be placed on the critical infrastructure list and regularly verify that list on a set schedule. The TRRC should share these data with the Public Utility Commission of Texas (PUCT) for conveyance to TDSPs.

- The PUCT must direct each TDSP to incorporate this information and develop a more granular load reduction plan. This protects all the identified critical infrastructure facilities and allows for increased flexibility to meet the reduction needs under critical conditions utilizing the extensive AMR system. The PUCT must verify this effort and ensure it has been updated on a regular set schedule.

- The PUCT and RRC need to have joint meetings during the development of and upon completion or update if items 1 and 2 above to ensure that the plans are coordinated between the industries.

- In the lead up to such an event ERCOT should strategically deploy units (particularly gas units) financially compensating them, even at minimum load with the ability to ramp up in drastic cold conditions to support reliability of the grid. This would keep key units hot and running rather than freeze up and risk a failure to cold start if brought off-line during the drastic cold conditions. These gas peakers (and other gas units) would be deployed outside of the economic stack for reliability purposes allowing them to be compensated for the procurement of their gas and transport.

- The RRC and the PUCT must coordinate on the update of the gas delivery prioritization list to ensure that delivery of gas for all power plants is higher than in the RRC’s current curtailment policy, regardless of the firmness of service. This list must be verified on a regular set basis.

While this does not solve all the issues that demand attention, these low costs and easier–to–implement recommendations should be part of a comprehensive package to help improve the resiliency of our grid. A major portion of this crisis is a direct result of a breakdown of communication. Collectively, the energy industry lapsed and only collectively can we solve this.

For more information or to comment on this article, please contact:

Jolly Hayden, Managing Director | CONTACT

Jolly Hayden, Managing Director | CONTACT

GDS Associates, Inc. – Austin, TX

512-541-3157 | jolly.hayden@gdsassociates.com

GET OUR NEWSLETTER

RECENT POSTS

- Protect the Grid: Act on Facility Ratings Today

- Why MOD-026-2 Matters: Raising the Bar for Generator and IBR Modeling Reliability

- Exploring the 2026-2028 Reliability Standards Development Plan

- Blackstart Resource Availability During Extreme Cold Weather Conditions

- DOE Pushes FERC to Accelerate Large Load Grid Access

Archives

- December 2015 (8)

- June 2025 (7)

- January 2016 (6)

- July 2016 (6)

- March 2021 (6)

- May 2022 (6)

- August 2020 (5)

- March 2015 (4)

- January 2019 (4)

- June 2019 (4)

- August 2019 (4)

- February 2020 (4)

- May 2020 (4)

- June 2020 (4)

- December 2020 (4)

- July 2021 (4)

- October 2021 (4)

- April 2024 (4)

- December 2024 (4)

- May 2025 (4)

- April 2015 (3)

- August 2016 (3)

- February 2017 (3)

- July 2017 (3)

- February 2018 (3)

- February 2019 (3)

- November 2019 (3)

- March 2020 (3)

- April 2020 (3)

- September 2021 (3)

- December 2021 (3)

- August 2022 (3)

- December 2022 (3)

- April 2023 (3)

- July 2023 (3)

- December 2023 (3)

- September 2024 (3)

- October 2025 (3)

- December 2025 (3)

- May 2014 (2)

- February 2016 (2)

- March 2016 (2)

- September 2016 (2)

- November 2016 (2)

- January 2017 (2)

- July 2018 (2)

- November 2018 (2)

- March 2019 (2)

- May 2019 (2)

- July 2020 (2)

- September 2020 (2)

- April 2021 (2)

- August 2021 (2)

- October 2024 (2)

- September 2025 (2)

- February 2014 (1)

- April 2014 (1)

- July 2014 (1)

- August 2014 (1)

- November 2014 (1)

- February 2015 (1)

- May 2015 (1)

- June 2015 (1)

- November 2015 (1)

- October 2016 (1)

- December 2016 (1)

- October 2018 (1)

- December 2018 (1)

- April 2019 (1)

- July 2019 (1)

- September 2019 (1)

- October 2020 (1)

- November 2020 (1)

- February 2021 (1)

- April 2022 (1)

- July 2022 (1)

- October 2022 (1)

- August 2023 (1)

- October 2023 (1)

- July 2025 (1)

- November 2025 (1)

- January 2026 (1)

Categories

- Newsletter - TransActions (85)

- News (78)

- Employee Spotlight (35)

- Energy Use & Efficiency (28)

- Energy, Reliability, and Security (18)

- Other Specialized Services (11)

- Environment & Safety (10)

- Power Supply (8)

- Transmission (8)

- NERC (7)

- Utility Rates (7)

- Cyber Security (5)

- Energy Supply (4)

- Hi-Line: Utility Distribution Services (4)

- Battery Energy Storage (3)

- Uncategorized (2)

- Agriculture (1)

- Hi-Line: Seminars & Testing (1)