- Home

- Services

- Hi-Line Engineering

- About

- Careers

- Contact

- Requests For Proposals

Controlling Lightning Induced Outages on Overhead Lines

by GDS Associates, Inc | January 19, 2016 | Energy Supply

Overvoltage protection, often called lightning protection, plays an important role in the design and operation of an electric system. Power distribution systems are asked to perform flawlessly in some of the most hostile weather environments. For many areas in North America, 20% of all power outages can be directly attributed to lightning. Not only does lightning cause an inconvenience to a customer, it typically damages utility electrical equipment as well as potentially, retail customers’ personal residences and electronics. Good lightning protection helps save equipment and reduces outages; while inadequate lightning protection costs money.

Overvoltage protection, often called lightning protection, plays an important role in the design and operation of an electric system. Power distribution systems are asked to perform flawlessly in some of the most hostile weather environments. For many areas in North America, 20% of all power outages can be directly attributed to lightning. Not only does lightning cause an inconvenience to a customer, it typically damages utility electrical equipment as well as potentially, retail customers’ personal residences and electronics. Good lightning protection helps save equipment and reduces outages; while inadequate lightning protection costs money.

Understanding Lightning

In 1749, Benjamin Franklin invented a pointed lightning rod conductor, also called a “Franklin rod,” as part of his groundbreaking exploration of electricity. The patent on Franklin rods was later improved upon by Nikola Tesla. Today Franklin Rods are still used on new buildings for lightning protection. These early inventors understood a lightning as static electricity which could to a degree be directed safely to earth. In order to protect the electric system from lightning, an understanding of what lightning is and how it discharges is required. During thunderstorm conditions, the positive charges in a cloud tend to migrate toward the top of the cloud while the negative charges concentrate in the bottom. A thunder cloud can be 6 to 7 miles tall, which gives it the capacity to generate a tremendous charge, measured in millions of volts.

Since like charges repel, the negative charges on the ground get pushed away by the force of the negative charges in the bottom of the cloud. This leaves the ground positively charged and since opposite charges attract, the negative charges of the cloud move toward the positive charges of the ground. This first invisible stroke is called the step leader. A negative step leader extends down from the cloud and a positive step leader extends up from objects on the earth. As soon as the negative and positive portions of the step leader connect, the path to the ground is completed and the negative charges race down the path causing a visible lightning stroke, referred to as the return stroke. The fast moving charges conduct until the negative charge is neutralized to earth. Once this has happened, the lightning flash ends.

Lightning’s Electrical Characteristics

When a lightning discharge occurs, electrons flow in the plasma of the lighting. This flow of electrons is commonly referred to as an electrical current. This electrical current is an extremely fast wave of energy. Peak current will occur in 8 micro- seconds (0.000008 seconds or 8 µs). These fast moving waves require lightning arresters to operate extremely fast when subject to a current/voltage surge. Further failures of components on the system occur nearly instantaneously.

Ground Flash Density (GFD)

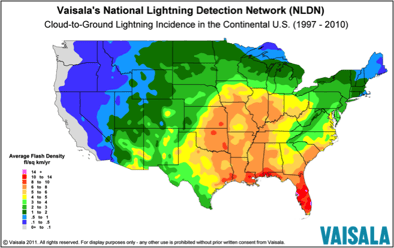

The frequency of lightning will determine influence an electric utility’s investment in lightning protection. For many years a lightning detection network has been deployed in North America. These networks use AM radio frequency to provide detailed ground flash density maps measured in ground flashes per square kilometer per year. In addition this network can provide the date, time, location, number of strokes, and estimated stroke peak current. Figure 1 is an example of the ground flash density for the United States for a period of 1997-2010.

Lightning Strikes to a Distribution Line

Lightning can strike a distribution system in one of two ways. It can strike an object in close proximity to the line resulting in an induced strike, or it can strike directly on the line. Induced voltages are more common than direct lightning strikes. A direct lightning strike to a line will likely result in peak voltage exceeding 1,000 kV which exceeds the typical 300kV insulation voltage of most distribution lines resulting in an insulation flashover which is often described as a ball of fire on the top of the pole.

Because utility poles are not always the tallest structures in the area an electric utility system is more likely to experience an induced strike. Tall trees will shield power lines from direct lightning strikes. A roadway with a power line at the edge of the road right-of-way with a line of trees adjacent to the power line is an example of shielding. Research has shown that a row of 66-foot tall (20m) trees located within 50 feet (15m) of a pole line will provide nearly 100% shielding (i.e. no direct strikes to the power line). However, shielding provided by trees does not mean a flashover will not occur. Lightning can induce voltages onto the distribution system when the lightning strike is near the distribution line. An average lightning strike with 30,000 amps striking an object 100 feet from a theoretical distribution line can induce 350 kV on to the distribution line.

Because utility poles are not always the tallest structures in the area an electric utility system is more likely to experience an induced strike. Tall trees will shield power lines from direct lightning strikes. A roadway with a power line at the edge of the road right-of-way with a line of trees adjacent to the power line is an example of shielding. Research has shown that a row of 66-foot tall (20m) trees located within 50 feet (15m) of a pole line will provide nearly 100% shielding (i.e. no direct strikes to the power line). However, shielding provided by trees does not mean a flashover will not occur. Lightning can induce voltages onto the distribution system when the lightning strike is near the distribution line. An average lightning strike with 30,000 amps striking an object 100 feet from a theoretical distribution line can induce 350 kV on to the distribution line.

By designing a high level of critical impulse flashover voltage (CFO) of a structure, it is possible for the structure to withstand induced voltage surges from lightning. In general, the goal is to maintain at least a CFO of 300 kV. However, areas with poor soils characterized as having high impedance, will require a CFO closer to 420 kV.

Distribution Line Insulation Level

The CFO is a combination of the insulation capabilities include porcelain insulators, wood, fiberglass, and polymer insulators. Each element has its own insulation strength for fast traveling lightning surges. When the different insulating components are used in series it is important to remember that the resulting insulation is not simply the sum of each component’s insulation level.

Obviously, increasing the CFO will improve the lightning performance for both direct and indirect lightning strikes. It is important to properly design the distribution system to maximize the CFO from each element. For example, a simple 12 kV tangent structure where the pole top insulator is in series with 30 inches of the wood when measured from the bottom of the metallic pole top pin to the grounding conductor at the neutral attachment can have a CFO of 285 kV. However, grounded down guys are major factor in reducing a structure’s CFO because they are generally attached high on the pole near the phase conductor. This reduces the amount of wood insulation between the phase associated hardware and the grounded down guy. When a grounded guy is attached 15 inches from the phase associated hardware the CFO is reduced to 195 kV. A better design option is to install a guy strain insulator which will increase the CFO of the structure to 300 kV. This simple addition greatly improves the ability of the structure to withstand a lightning flashover.

Spacing of Line Arresters

Adding lightning arresters will further help mitigate flashovers. The closer together the arresters are located, the shorter the distance the current surge has to travel and therefore develops a lower voltage surge magnitude. Lightning arresters can greatly reduce flashovers from induced lightning surges. A spacing of 1,600 feet (every 4th or 5th pole) provides nearly an 80% reduction in flashovers as compared to a line without surge arresters. Decreasing the spacing to 800 feet (every 2nd or 3rd pole) doubles the investment in arresters with little improvement in system performance. For direct lightning strikes, the lightning arresters would have to be placed on nearly every pole to prevent the voltage from exceeding the CFO of the structures.

Adding lightning arresters will further help mitigate flashovers. The closer together the arresters are located, the shorter the distance the current surge has to travel and therefore develops a lower voltage surge magnitude. Lightning arresters can greatly reduce flashovers from induced lightning surges. A spacing of 1,600 feet (every 4th or 5th pole) provides nearly an 80% reduction in flashovers as compared to a line without surge arresters. Decreasing the spacing to 800 feet (every 2nd or 3rd pole) doubles the investment in arresters with little improvement in system performance. For direct lightning strikes, the lightning arresters would have to be placed on nearly every pole to prevent the voltage from exceeding the CFO of the structures.

Conclusion

The combination of a high CFO (greater than 300 kV) coupled with properly spaced lightning arresters will greatly reduce the number of outages caused by lightning. The need for additional lightning arresters and high CFO levels is dictated by the ground flash density where the line is located and the desire to reduce lightning caused outages.

For more information or to comment on this article, contact:

Kevin Mara, Principal Engineer, HiLine Engineering | CONTACT

Kevin Mara, Principal Engineer, HiLine Engineering | CONTACT

GDS Associates, Inc. – Marietta, GA

770.425.8100

GET OUR NEWSLETTER

RECENT POSTS

- Protect the Grid: Act on Facility Ratings Today

- Why MOD-026-2 Matters: Raising the Bar for Generator and IBR Modeling Reliability

- Exploring the 2026-2028 Reliability Standards Development Plan

- Blackstart Resource Availability During Extreme Cold Weather Conditions

- DOE Pushes FERC to Accelerate Large Load Grid Access

Archives

- December 2015 (8)

- June 2025 (7)

- January 2016 (6)

- July 2016 (6)

- March 2021 (6)

- May 2022 (6)

- August 2020 (5)

- March 2015 (4)

- January 2019 (4)

- June 2019 (4)

- August 2019 (4)

- February 2020 (4)

- May 2020 (4)

- June 2020 (4)

- December 2020 (4)

- July 2021 (4)

- October 2021 (4)

- April 2024 (4)

- December 2024 (4)

- May 2025 (4)

- April 2015 (3)

- August 2016 (3)

- February 2017 (3)

- July 2017 (3)

- February 2018 (3)

- February 2019 (3)

- November 2019 (3)

- March 2020 (3)

- April 2020 (3)

- September 2021 (3)

- December 2021 (3)

- August 2022 (3)

- December 2022 (3)

- April 2023 (3)

- July 2023 (3)

- December 2023 (3)

- September 2024 (3)

- October 2025 (3)

- December 2025 (3)

- May 2014 (2)

- February 2016 (2)

- March 2016 (2)

- September 2016 (2)

- November 2016 (2)

- January 2017 (2)

- July 2018 (2)

- November 2018 (2)

- March 2019 (2)

- May 2019 (2)

- July 2020 (2)

- September 2020 (2)

- April 2021 (2)

- August 2021 (2)

- October 2024 (2)

- September 2025 (2)

- February 2014 (1)

- April 2014 (1)

- July 2014 (1)

- August 2014 (1)

- November 2014 (1)

- February 2015 (1)

- May 2015 (1)

- June 2015 (1)

- November 2015 (1)

- October 2016 (1)

- December 2016 (1)

- October 2018 (1)

- December 2018 (1)

- April 2019 (1)

- July 2019 (1)

- September 2019 (1)

- October 2020 (1)

- November 2020 (1)

- February 2021 (1)

- April 2022 (1)

- July 2022 (1)

- October 2022 (1)

- August 2023 (1)

- October 2023 (1)

- July 2025 (1)

- November 2025 (1)

- January 2026 (1)

Categories

- Newsletter - TransActions (85)

- News (78)

- Employee Spotlight (35)

- Energy Use & Efficiency (28)

- Energy, Reliability, and Security (18)

- Other Specialized Services (11)

- Environment & Safety (10)

- Power Supply (8)

- Transmission (8)

- NERC (7)

- Utility Rates (7)

- Cyber Security (5)

- Energy Supply (4)

- Hi-Line: Utility Distribution Services (4)

- Battery Energy Storage (3)

- Uncategorized (2)

- Agriculture (1)

- Hi-Line: Seminars & Testing (1)